CONFIRM YOUR SPRAYER COVERAGE

As first seen in the Orchardist, November 2018

Jack Hughes and Jason Bennett Fruition Horticulture, Hawkes Bay

David Manktelow Applied Research and Technologies Ltd, Hawkes Bay

Back in the day

In the early 1990’s the NZ apple industry faced a USA market access crisis caused by orgnophosphate resistant leaf roller caterpillars – at that time about 25% of the crop went to the US and failure there would have cost dearly. At that time 820 mm diameter fans (think Winstone Typhoon (Picture 1) and Metters sprayers) were pretty common and the trees were bigger with lots of wood in the tops. A big part of the problem was caused by too little spray reaching the tops of the trees and the then Apple and Pear Marketing Board introduced a mandatory sprayer calibration requirement – with the aim of better matching sprayers (travel speeds, application volumes, nozzle output distributions etc) to the target problem.

In the early 1990’s the NZ apple industry faced a USA market access crisis caused by orgnophosphate resistant leaf roller caterpillars – at that time about 25% of the crop went to the US and failure there would have cost dearly. At that time 820 mm diameter fans (think Winstone Typhoon (Picture 1) and Metters sprayers) were pretty common and the trees were bigger with lots of wood in the tops. A big part of the problem was caused by too little spray reaching the tops of the trees and the then Apple and Pear Marketing Board introduced a mandatory sprayer calibration requirement – with the aim of better matching sprayers (travel speeds, application volumes, nozzle output distributions etc) to the target problem.

Reviewing and optimising spraying practices can have a number of benefits

IFP Introduction

The introduction of Integrated Fruit Production (IFP) in the late 90’s bought about a massive change in the type of chemistries used to protect crops and the way in which they were used. Softer and more specific products were introduced, and use was based on need rather than calendar date. IFP was a big deal and the transition was quite quickly and effectively achieved through industry discussion groups involving researchers, advisors and growers – supported by good science from a strong research programme.

Spraying then was primarily ‘dilute’. This is defined as high volume spraying where canopies are sprayed with water rates that approach the point of run-off. When trees are sprayed dilute to runoff the outer canopy should be well wetted and the inner canopy should be well covered but will receive about half the chemical per square centimetre than the outer, more easily sprayed zones. Agri-chemicals are tank mixed at the label rate per 100 litres of spray mix.

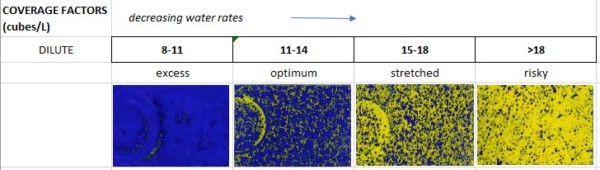

Research conducted in the 1990’s matched the size of different tree canopies to the spray volumes required to spray to the point of runoff. Tree Row Volume (TRV) calculations were carried out over many NZ orchards and compared with international data. Typical plantings in the 90’s had TRV’s in the range 15,000-35,000 cubic metres per hectare. Analysis of spray application methodology and pest and disease control showed that Canopy Coverage Factors (CCF, water rates expressed as the cubic metres of TRV that can be covered per litre of dilute spray mix) in the range 11-14 cubic metres of canopy per litre of spray achieved good pest and disease control. As a result, water rates of 2,000 L/ha (24,000 m3 / CCF of 12) became the industry ‘stock standard’ sprayer calibration.

These findings could be validated in with the use of Water Sensitive Papers (WSP) which stain blue when wetted. WSPs allowed growers to check that they were achieving adequate coverage with their own sprayer setups in their various orchard blocks.

Illustration of water sensitive paper interpretations for dilute fungicide application

It became common practice to calibrate sprayers to the 2,000 L/ha benchmark and to calibration worksheets would typically ‘solve’ the 2,000L rate for the range of row widths present in the orchards concerned. This approach arguably introduced a disconnect between the underlying TRV and CCF principles and their application to the range of blocks being sprayed.

When sprayers were calibrated to deliver a pre-determined, mid-range water rate for a range of row widths without considering tree size (TRV), it created a situation where smaller / younger trees were often over-sprayed and larger, older trees received a barely adequate coverage.

This situation was reported by Manktelow & Pratt in 1997 in their paper, “The tree row volume spraying system and its potential use in New Zealand”, presented at the 50th NZ Plant Protection Conference. Click here

Dilute spray volumes at full leaf used on surveyed orchard blocks versus the estimated spray volume required for a coverage factor of 11 m3 of TRV covered per litre of dilute spray mix.

Enter Concentrate Spraying

The introduction of high-quality ceramic hollow cone nozzles and air shear tower sprayers in the early 1990s made it practical for growers to apply fine droplet sprays in volumes 2X-3X lower than dilute (runoff) spray volumes. More uniform and smaller droplet sizes significantly improved spray coverage and spraying work rate efficiency (hectares treated per hour). Water rates were dropped from 2,000-2,500 L/ha to 666 or even 500 and chemical tank mixing rates were concentrated up so that the same amount of product was delivered per sprayed hectare.

Airblast sprayer fans have improved over the last 30 year, with 920 mm diameter fans fitted with straightening vanes the current industry standard. As tree canopies have become more regular and smaller, the use of vertical tower sprayers has become more practical and there is currently a lot of industry experimentation with new forms of single row and multiple row tower sprayers.

Whatever form of sprayer is used, chemical application rates and spray application volumes should still be adjusted to match different tree sizes and densities – and, for virtually all canopies, basic Tree Row Volume application rate adjustments should still apply.

Bigger fans, smaller trees

Improved fan design has increased the air output and uniformity of airblast sprayers. Pump capacities have also increased so that newer machines can be ‘calibrated up’ to cover the ground faster than in the past.

At the same time, the industry has moved strongly to more intensive growing systems using more dwarfing rootstocks, closer row spacings and slimmer canopies. It is now practical to actively use spraying travel speed as a tool to help optimise air outputs and spray deposits in different canopies.

Review time

It is timely to review the chemical application rates, spray volumes and travel speeds that you are using on the different canopies on your orchard – especially for the application of chemical thinners and other plant growth regulators.

The Tree Row Volume system for calculating chemical application rate requirements for different canopies is currently still the best method that we have. The Canopy Coverage Factor best suited to modern open hedge row canopy forms is around 14 m3 of TRV covered or litre of dilute spray mix, while a CCF of around 11 should be used for more traditional canopies with larger trees and scaffold wood.

When spraying a range of different tree sizes, it possible to adjust travel speeds to optimise fan air outputs for different sized canopies. As a rule of thumb, for a 920mm diameter airblast (mid pitch in high fan gear at 540 PTO RPM), trees on 4-5m row spacings can be effectively treated using speeds between 5-7km/hr. Air outputs from the same fan settings will usually be optimal in dwarf hedgerow canopies on 3-4m row spacings at travel speeds of between 7-9 km/hr.